How Embraer Reduces eVTOL Noise With PowerFLOW

- Aug 11, 2025

- 3 min read

Updated: Dec 3, 2025

Urban air mobility (UAM) is no longer science fiction, it's in development. But one major hurdle remains: noise. For electric vertical take-off and landing (eVTOL) aircraft to operate in cities, they must be quiet enough to gain public acceptance and meet urban noise regulations. That’s why Embraer has partnered with Dassault Systèmes to leverage SIMULIA PowerFLOW in the development of Eve Air Mobility’s next-generation eVTOL vehicle.

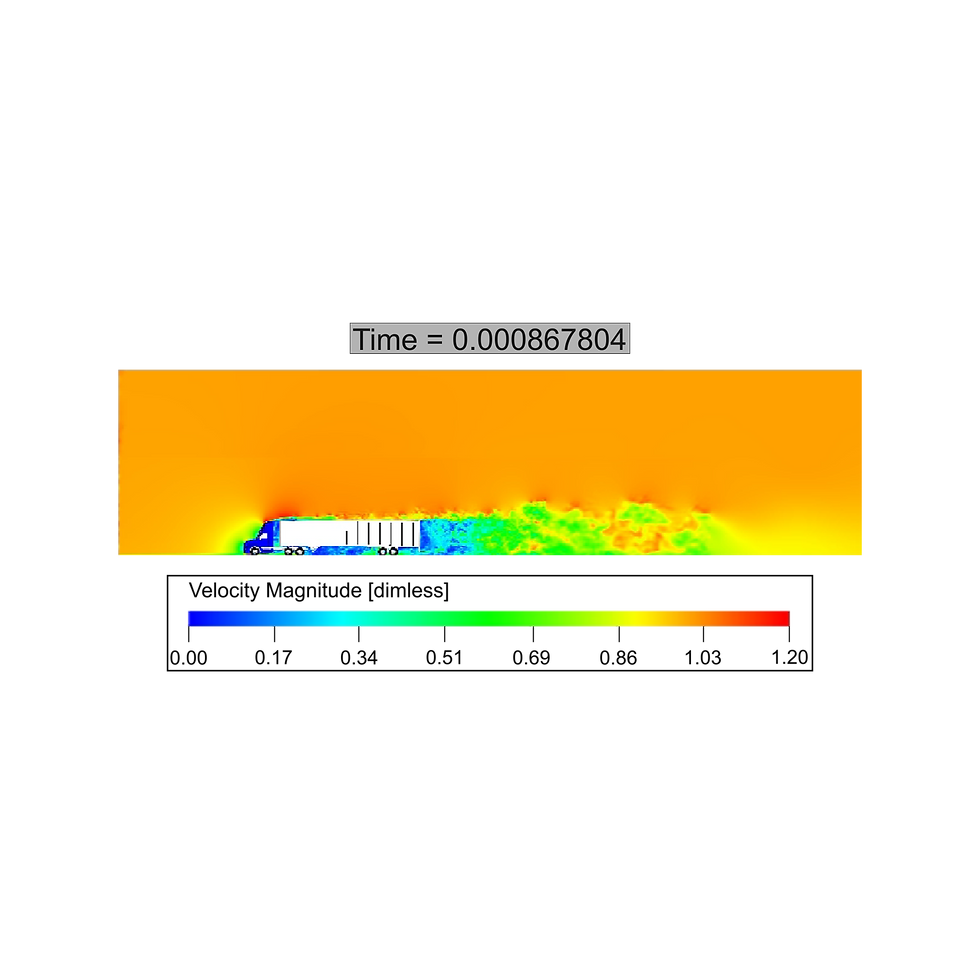

Through high-fidelity fluid dynamics simulation, Embraer is optimizing both performance and acoustics, helping create aircraft that are as quiet as they are efficient.

Simulating Aeroacoustics With PowerFLOW

At the heart of this collaboration is PowerFLOW, a CFD solution that models aerodynamic and acoustic behavior in full 3D, under realistic conditions. Embraer and Eve Air Mobility’s engineers use PowerFLOW to simulate:

Propeller performance during various flight stages

Sound generation and transmission in complex urban environments

The impact of design modifications on tonal and broadband noise

This digital workflow makes it possible to virtually test blade shapes, tip designs, and flight configurations before building a single prototype. That leads to faster iteration, lower development costs, and smarter trade-offs between lift, drag, and noise.

Why Noise Reduction is Critical for UAM

As David Ziegler, VP of Aerospace & Defense at Dassault Systèmes, puts it: “eVTOL aircraft offer a sustainable alternative to combustion-powered vehicles. But since they’re designed for urban operation, minimizing noise is critical. PowerFLOW helps optimize key design aspects in a virtual setting.”

For Eve Air Mobility, reducing acoustic impact isn’t just a technical requirement, it’s a core design philosophy. The aircraft must be comfortable, accessible, and community-friendly, meaning low exterior noise for the public and low cabin noise for passengers.

Validated Simulations, Accelerated Development

Numerical results are only as good as their real-world accuracy. That’s why the team at Embraer validates simulation results against experimental data. According to Micael Gianini, Senior Manager of Interiors, Noise, and Vibration at Embraer: “Validated numerical models have shown impressive accuracy and have significantly streamlined the product definition process.”

By integrating PowerFLOW into the early stages of product design, the team can evaluate noise behavior across many conditions and identify potential acoustic issues before physical testing. This reduces costly redesigns and supports more confident decision-making.

From Prototype to Production

Embraer recently announced that Eve’s first eVTOL production facility will be built in Taubaté, Brazil. The first full-scale prototype is already under construction, with a comprehensive flight test campaign scheduled for 2024. Eve expects to bring its eVTOL to market by 2026.

Simulation tools like PowerFLOW are playing a crucial role in helping the program stay on schedule, by enabling early validation, reducing physical iteration, and guiding critical design choices.

A Strategic Step Toward Cleaner, Quieter Cities

Eve Air Mobility is Embraer’s dedicated venture into sustainable air transport. With its eVTOL aircraft, integrated air traffic management system, and infrastructure planning initiatives, Eve is building a full ecosystem for next-generation urban aviation.

The collaboration with Dassault Systèmes and the use of PowerFLOW demonstrate how virtual testing accelerates real-world innovation, not just making eVTOLs possible, but making them practical, acceptable, and scalable in everyday life.

Ready to Simulate Quieter Skies?

Whether you're designing next-gen aircraft or tackling complex aeroacoustic challenges, simulation can make the difference. If you'd like to explore how PowerFLOW can support your goals, feel free to reach out via the contact form or by emailing marketing@4realsim.com.

Comments