Improving Side Glass Visibility with PowerFLOW

- Aug 7, 2025

- 2 min read

Updated: Dec 3, 2025

When a vehicle decelerates in wet conditions, visibility through the side windows often deteriorates due to the accumulation of rain, mist, and road grime. This effect, known as compliant soiling, poses a safety risk for drivers and presents a complex challenge for automotive design teams. With SIMULIA PowerFLOW, engineers can simulate this phenomenon under realistic braking conditions and develop effective strategies to reduce visibility loss.

Understanding the Customer Challenge

A PowerFLOW customer approached Dassault Systèmes with complaints from their end-user: side glass visibility was rapidly worsening during braking, especially in rainy environments. Drivers were experiencing dangerous blind spots caused by water and dirt collecting on the side windows when slowing down from highway speeds.

The root cause lay in the change in airflow dynamics. At high speeds, turbulent air tends to sweep moisture and debris away. But when the vehicle slows, airflow weakens, allowing more contaminants to settle on the glass.

Simulating Realistic Braking Behavior

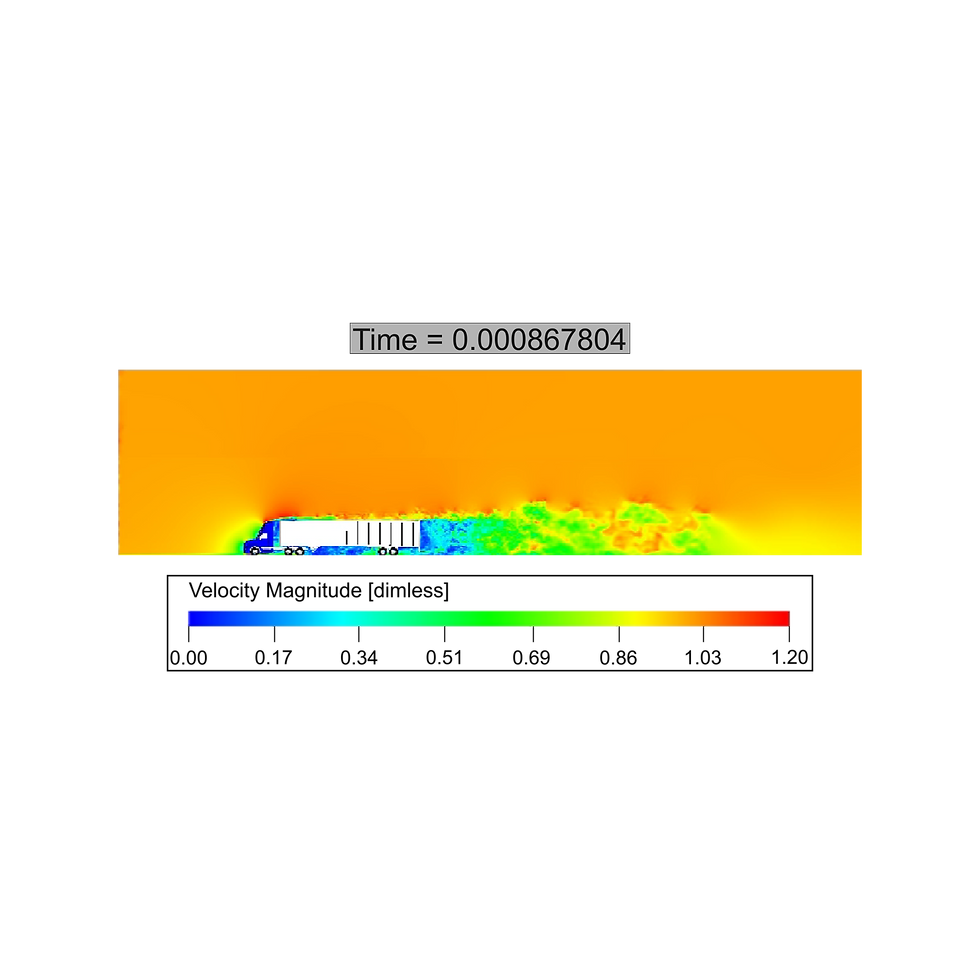

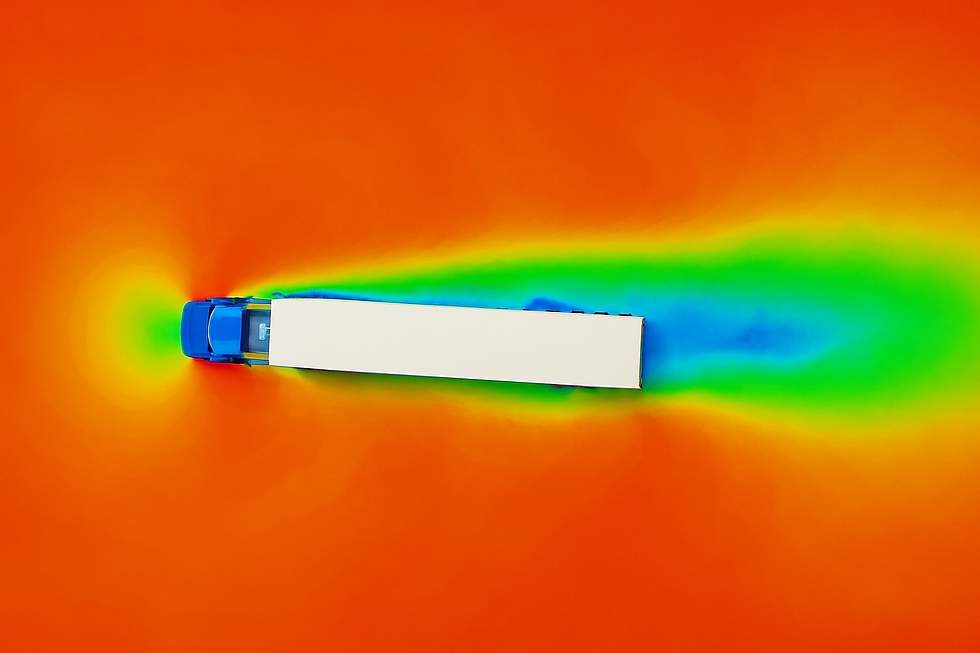

To investigate this, the simulation team developed a variable speed soiling methodology, replacing static test cases with dynamic braking conditions. Using a non-inertial reference frame and upstream turbulence, the simulation accurately replicated how soiling accumulates as aerodynamic forces diminish during deceleration.

This transient, high-fidelity approach revealed how quickly side glass becomes vulnerable to contamination in real-world driving scenarios.

Key Simulation Parameters

To ensure realistic results, the simulation environment included detailed inputs that mirrored physical conditions:

Rain modeling

Rain emitters placed on the front, top, and driver’s side

Rainfall intensity of 17 mm/hr (heavy rain)

Droplet diameter of 0.3 mm

Splash, breakup, and film models to track rainwater behavior

Tire mist generation

Front tires emitted road mist based on speed, water depth, and tire width

Particle size of 0.165 mm to simulate fine spray

Wiper functionality

Set to 0.5 strokes per second

97° sweep angle to replicate realistic wiping patterns

These combined elements allowed the simulation to capture moisture buildup, particle tracking, and glass-film behavior with high accuracy.

Design Insights and Mitigation Strategies

The simulation revealed specific areas of concern and helped define actionable design changes to reduce side glass soiling. Key findings included:

Aerodynamic refinements

Smoother flow around side mirrors and windows reduced turbulent zones where moisture accumulates

Wiper system optimization

Adjusting stroke frequency and range improved debris removal during variable rainfall

Tire spray management

Tire tread patterns and deflectors limited road mist from reaching the glass surface

Outputs like film thickness maps after 4 seconds, Y-slice velocity fields, and top-view flow patterns validated the simulation and supported these recommendations.

Conclusion

Compliant soiling is more than a cosmetic issue, it impacts driver safety, especially during adverse weather. By applying advanced simulation techniques in PowerFLOW, automotive engineers can predict and control soiling behavior during braking events. The variable speed soiling approach enables teams to develop better wipers, smarter aerodynamics, and cleaner glass, all before physical testing begins.

Clearer windows mean safer journeys. PowerFLOW helps make that possible.

Acknowledgment: This article is based on the Dassault Systemes powerpoint: EST Soiling Performance – a variable speed study.

Interested in PowerFLOW Simulations for Compliant Soiling?

Contact us via our contact form or email us at marketing@4realsim.com to discover how 4RealSim can support your simulation-driven design process with PowerFLOW, helping you optimize visibility and safety before physical testing begins.

Comments