Modeling Laminar Separation in PowerFLOW

- Aug 7, 2025

- 2 min read

Updated: Dec 3, 2025

Laminar separation is a critical aerodynamic and acoustic challenge in low-Reynolds-number flows, like those found in eVTOL rotors and wind turbine blades. Historically, this transition from laminar to turbulent flow was hard to simulate accurately and required manual workarounds.

With recent improvements in PowerFLOW, it’s now possible to capture these effects directly and reliably.

Why Laminar Separation Matters

At low Reynolds numbers, typically below one million, the boundary layer can separate from a surface before transitioning to turbulence. This results in a laminar separation bubble (LSB), which disrupts flow attachment, affects lift and drag, and amplifies noise.

You see this clearly on:

eVTOL propeller blades with slow rotational speeds

Wind turbine blades rotating at a few RPM

In both cases, accurate modeling of the separation bubble is essential for predicting thrust, efficiency, and acoustic behavior.

Modeling Laminar Separation With PowerFLOW

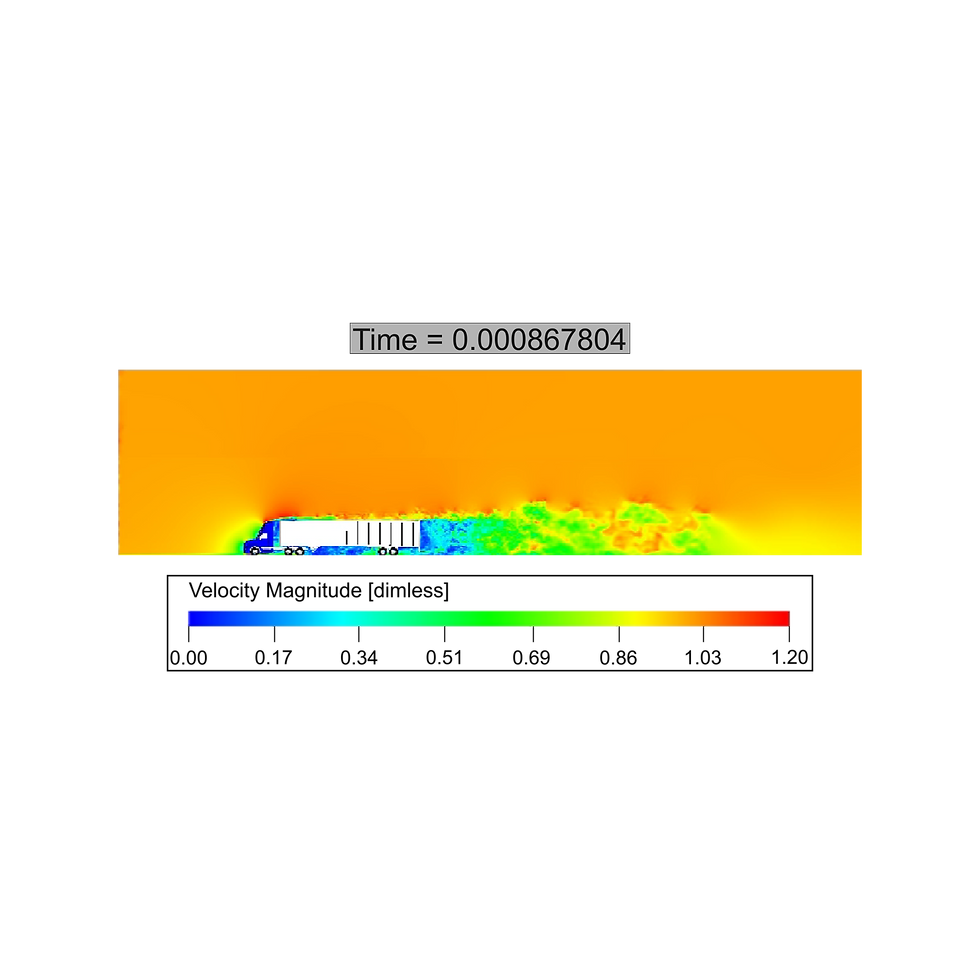

PowerFLOW uses a particle-based solver and the Very Large Eddy Simulation (VLES) turbulence model, well suited for resolving unsteady flow structures. Previously, capturing laminar separation required inserting physical “trip” elements, extra geometry to force the boundary layer to transition. That approach was limited in accuracy and cumbersome to apply.

To solve this, SIMULIA introduced a turbulence model extension for VLES that automatically simulates transition from laminar to turbulent flow. The result:

No geometry modification needed

Consistent laminar-to-turbulent behavior captured in one simulation

Suitable for both aerodynamic and aeroacoustic studies

Validating the Transition-Aware VLES Model

To verify the updated model, a propeller was tested at a chord-based Reynolds number of ~70,000. At this condition, a pronounced laminar separation bubble was expected. PowerFLOW results were benchmarked against experimental velocity and noise data.

Findings:

The simulated velocity field showed close agreement with measured data

Predicted far-field acoustic spectra matched microphone recordings

The automatic transition model outperformed manual tripping in accuracy and realism

These results were published in Aerospace Science and Technology, Volume 130, November 2022.

Why This Matters for eVTOL and Wind Turbine Design

Laminar separation affects both aerodynamic forces and noise generation. In eVTOL applications, this directly impacts urban noise regulations and passenger comfort. For wind turbines, minimizing blade noise is often a gating factor in public approval of new installations.

With PowerFLOW’s transition-aware VLES model, engineers can now:

Design and optimize low-noise rotor geometries

Run predictive acoustic simulations without artificial trip elements

Reduce setup time and complexity while improving model accuracy

Need Help Modeling Laminar Separation?

4RealSim offers deep expertise in PowerFLOW, with hands-on experience in both aerodynamic and aeroacoustic simulations. Fill out the contact form or email us at marketing@4realsim.com to get expert support tailored to your needs.

Comments